Understanding the Role of Your PCV Valve in Engine Performance****

Curious about how your engine maintains smooth operation despite the intense pressure and explosive combustion within? The PCV valve plays a crucial role in this process. This small but powerful component manages blow-by gases, prevents oil contamination, and helps maintain peak engine performance.

When the PCV valve fails, you may experience:

- Increased oil consumption

- Reduced fuel efficiency

- Potentially serious engine damage

These issues can significantly impact your vehicle. Exploring how this unassuming valve protects your engine can provide valuable insights into its functionality.

The PCV valve effectively redirects gases from the crankcase back into the intake manifold, allowing for combustion. If it becomes clogged or malfunctioning, it can lead to excessive oil build-up, contributing to decreased performance.

Think of the PCV valve as a filter that regulates what enters your engine. By managing blow-by gases, it helps maintain a clean and efficient combustion process. Properly functioning, the PCV valve enhances your engine’s longevity and efficiency.

In summary, maintaining your PCV valve is essential for optimal engine performance. By being aware of its function and recognizing potential issues, you can safeguard your vehicle’s performance and reliability. Regular inspections can identify any problems before they escalate, ensuring your engine runs at its best.

The Fundamentals of Crankcase Ventilation Systems

Crankcase Ventilation Systems: A Key to Engine Efficiency****

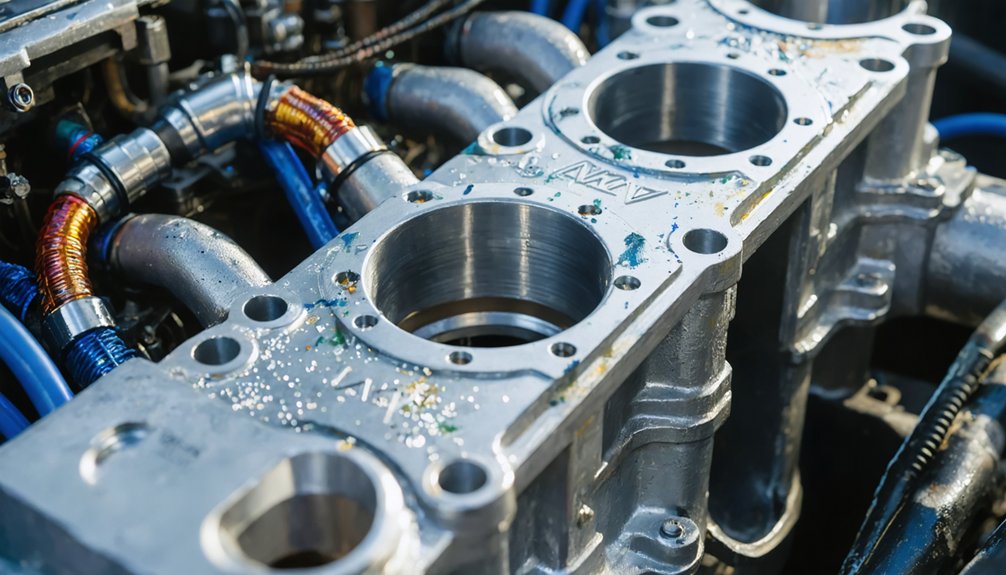

Managing unwanted gases is essential for every internal combustion engine. Blow-by gases—unburned fuel and combustion byproducts—escape past piston rings into the crankcase during operation. Without proper ventilation, these gases result in oil contamination, sludge buildup, and ultimately, a shorter engine life.

Modern crankcase ventilation systems utilize a one-way PCV (Positive Crankcase Ventilation) valve. This valve regulates pressure based on engine vacuum and load conditions. Acting as the system’s control point, the crankcase ventilation valve directs gases back to the intake manifold for re-combustion instead of allowing them to escape into the environment as pollutants.

The brilliance of this system lies in its simplicity. The crankcase ventilation system protects internal components in the following ways:

- Prevents oil leaks

- Reduces harmful emissions

- Manages pressure effectively

These benefits collectively contribute to enhanced engine performance and longevity.

Armor Lubricants recognizes the importance of a well-functioning crankcase ventilation system. Effective crankcase ventilation is paramount for optimal engine operation and reduced environmental impact.

By prioritizing proper pressures and flow management, you can help ensure a cleaner and more efficient combustion process. This system ultimately positions your engine for greater reliability and reduced maintenance needs.

Embrace the power of effective crankcase ventilation for your engine today!

How PCV Valves Regulate Blow-By Gases

How PCV Valves Regulate Blow-By Gases****

Engine maintenance often highlights various components, yet the PCV valve plays a critical role in maintaining engine health. This one-way valve regulates blow-by gases flowing from the crankcase to the intake manifold, effectively preventing harmful pressure buildup.

The PCV system operates dynamically based on engine conditions:

- At idle, the valve restricts flow due to lower manifold pressure, which maintains ideal air-fuel ratios.

- As you accelerate and engine speeds rise, the valve opens wider, facilitating efficient recycling of gases.

Such an intelligent design serves multiple functions:

- It maintains negative crankcase pressure.

- It reduces oil leaks.

- It enhances combustion efficiency.

- It prevents harmful emissions from escaping into the atmosphere.

Regular maintenance of your PCV valve guarantees improved performance, prolongs engine life, and minimizes environmental impact.

Signs of a Failing PCV Valve

Signs of a Failing PCV Valve

A failing PCV valve will noticeably deteriorate your engine’s performance.

Expect to experience rough idling and reduced power during acceleration.

You may find mysterious oil leaks beneath your vehicle.

As pressure builds in the crankcase, oil can escape past seals and gaskets designed to contain it.

Look out for blue-gray smoke drifting from your exhaust.

This indicates that oil burns in the combustion chambers due to improper crankcase ventilation.

In summary, watch for these signs:

- Rough idling

- Decreased acceleration power

- Oil leaks

- Blue-gray smoke from the exhaust

Addressing these issues promptly can help maintain your vehicle’s performance.

Trust Armor Lubricants to provide the solutions you need for a healthy engine.

Poor Engine Performance

The Impact of a Failing PCV Valve on Engine Performance****

The PCV valve, though small, plays a crucial role in maintaining engine performance. If it begins to fail, significant performance issues can arise that directly impact your driving experience.

When the PCV valve malfunctions, the air-fuel mixture becomes disrupted. As a result, you may experience rough idling characterized by unstable RPMs and noticeable vibrations. Engine misfires frequently occur due to the imbalanced combustion process.

Struggling to regulate crankcase gases, the faulty valve can lead to deteriorating fuel economy, resulting in more frequent trips to the gas station.

Watch for bluish-gray smoke from your exhaust, particularly during acceleration. This smoke indicates that the blow-by gases aren’t being adequately managed. Additionally, if you find yourself topping up oil more often than usual, a stuck-open PCV valve could be allowing excessive vapor to escape from the crankcase.

Symptoms of a Malfunctioning PCV Valve:

- Rough idling with unstable RPMs

- Frequent engine misfires

- Deteriorating fuel economy

- Bluish-gray smoke from the exhaust

- Increased oil consumption

Maintaining your PCV valve can bolster engine performance and enhance your overall driving experience. Regular inspections and timely replacements play a key role in ensuring optimal engine functionality.

Trust Armor Lubricants to provide the necessary support for your engine.

Unusual Fluid Leaks

Unusual Fluid Leaks in Your Vehicle

A failing PCV valve often signals itself through noticeable fluid leaks around your vehicle. Look for oil spots beneath your parked car; excessive crankcase pressure forces oil past seals and gaskets, resulting in these leaks.

When the PCV valve sticks open, it draws too much vapor from the crankcase. This action can compromise oil seals and may trigger a P04DB code in modern vehicles.

Check the spark plugs; if you find them saturated with oil, the valve isn’t venting pressure effectively.

Listen for whirring or whistling sounds from your engine. Such noises often indicate PCV system failures, which lead to fluid leaks. Addressing these symptoms quickly protects your engine’s integrity and helps prevent serious damage to crucial components.

Key Symptoms to Watch For

- Oil spots under the vehicle

- Saturated spark plugs

- Whirring or whistling engine sounds

Taking prompt action when you notice these signs can save you from costly repairs. Understanding these symptoms allows you to maintain your vehicle effectively and enhance its longevity.

Visible Smoke Emissions

Identifying Failing PCV Valve Through Smoke Emissions

Distinctive smoke patterns from your exhaust reveal a failing PCV valve. When you see bluish-gray smoke, particularly during acceleration, the PCV valve may fail to regulate crankcase pressure effectively. Excessive oil vapor can then enter the combustion chamber instead of being recirculated.

Understanding the operation of a PCV valve helps identify these critical warning signs. A stuck open valve disrupts pressure balance. This condition causes oil to be drawn into the intake manifold, resulting in noticeable smoke and increased oil consumption as the engine burns more oil during combustion.

Watch for the following types of smoke emissions:

- Bluish-gray smoke: Indicates oil vapor entering the combustion chamber.

- Black smoke: Suggests that the PCV system disrupts the air-fuel ratio, leading to incomplete combustion.

Early detection of smoke emissions is essential. Addressing these issues promptly can prevent more severe engine damage linked to improper crankcase ventilation.

Always consider using Armor Lubricants for reliable performance and enhanced engine health.

Proper Maintenance and Inspection Techniques

Regular inspection of your PCV valve is crucial for maintaining optimal engine performance. Remove the valve and listen for a rattling sound, which indicates it’s functioning properly. If dirt accumulates, clean it with carburetor cleaner.

Check for significant wear and replace the valve per the manufacturer’s schedule, typically every 20,000 to 50,000 miles.

To maintain ideal crankcase pressure:

- Inspect connections for tightness.

- Look for cracks in hoses.

These actions prevent engine performance issues that could lead to costly repairs in the future.

Trust Armor Lubricants to help keep your system running smoothly and efficiently.

Inspection Steps Explained

Effective PCV Valve Inspection Steps

Inspecting the PCV valve demands careful attention and a methodical approach. First, locate the valve on the valve cover or intake manifold. Remove it cautiously, ensuring that you don’t damage the connected hoses.

During the inspection, listen for a rattling sound, which signifies proper PCV operation. Examine the valve for any signs of damage, wear, or blockages.

Don’t overlook the PCV valve hose. Check it meticulously for leaks, cracks, or deterioration that could jeopardize system performance.

If you find the valve dirty, clean it with carburetor cleaner. However, if you notice significant deterioration, opt for a complete replacement.

Watch for engine performance indicators such as increased oil consumption or unstable idle. These symptoms indicate that your PCV system requires immediate attention.

Key Inspection Steps:

- Locate and Remove the Valve: Carefully detach it from the valve cover or intake manifold.

- Listen for Sounds: Ensure there’s a rattling noise, confirming proper PCV operation.

- Inspect for Damage: Look for any signs of wear, blockages, or corrosion on the valve.

- Check the Hose: Thoroughly evaluate the PCV valve hose for leaks or cracks.

- Clean or Replace: Use carburetor cleaner if dirty. Replace the valve if significantly deteriorated.

- Monitor Engine Performance: Keep an eye out for increased oil consumption and unstable idle issues.

Focusing on these steps elevates your ability to maintain an efficient engine.

Trust the quality and effectiveness of Armor Lubricants to enhance engine performance and longevity.

DIY Replacement Guide

DIY Guide: Easily Replace Your PCV Valve****

Replacing your PCV valve is a simple maintenance task that any vehicle owner can tackle with basic tools and careful attention.

1. Locate the Valve:

Find the PCV valve on your engine’s valve cover or intake manifold.

2. Remove the Valve:

As you take it off, inspect connected hoses for signs of deterioration or leaks that could compromise the PCV system’s operation.

3. Prepare the New Valve:

Before installation, verify that the new valve is clean and free of oil. Apply a light coat of engine oil to the O-ring for optimal sealing.

4. Test the Valve:

Shake the new valve—if it rattles, it functions properly. Silence suggests the valve is defective.

5. Set a Replacement Schedule****:

Plan to replace your PCV valve every 20,000-50,000 miles, or sooner if you experience symptoms such as increased oil consumption or engine misfires.

6. Inspect the PCV Hose:

During maintenance, check the PCV hose for cracks or blockages that could hinder ventilation.

Following these steps ensures your PCV system operates efficiently and contributes to engine longevity. Regular maintenance helps avoid costly repairs down the line, allowing your engine to run smoothly for years to come.

Environmental Benefits of Effective PCV Systems

The Environmental Advantages of Effective PCV Systems****

Modern vehicles incorporate various components aimed at lessening their environmental impact, but the PCV valve stands out as a highly effective emissions control device. This crucial component actively recycles harmful blow-by gases back into the combustion chamber instead of releasing them into the atmosphere. Consequently, unburned hydrocarbon emissions see a significant reduction.

By maintaining an efficient PCV system, you enjoy multiple environmental benefits:

- Reduced oil leakage onto roadways due to lower crankcase pressure

- Enhanced fuel economy, resulting in a smaller carbon footprint through improved engine efficiency

- Compliance with strict emissions regulations without needing additional modifications

Since their adoption in the 1960s, PCV systems have revolutionized automotive environmental protection. Proper maintenance of your PCV system allows you to take command of your vehicle’s environmental impact while simultaneously safeguarding your engine’s performance.

Investing attention in your PCV system not only helps the environment but also promotes a cleaner driving experience for everyone on the road.

Selecting the Right PCV Valve for Your Engine

Choosing the right PCV valve is crucial for your engine’s health. The PCV valve controls pressure within your crankcase ventilation system, preventing harmful buildup that can cause engine damage.

Select a valve specifically designed for your engine’s make and model. OEM-certified crankcase vent valves deliver the most reliable performance, as they meet your vehicle’s exact specifications.

High-quality aftermarket options with enhanced features can improve flow rates. Always verify that aftermarket valves have been tested for compatibility with your engine. Key features to consider include:

- One-way mechanisms to prevent backflow

- Materials engineered to withstand oil and heat exposure

Keep track of replacement intervals, typically between 20,000 and 50,000 miles. Following manufacturer guidelines will help your engine maintain peak performance while effectively controlling emissions.

Frequently Asked Questions

What Are the Three Signs of a Bad PCV Valve?

Signs of a Failing PCV Valve

A malfunctioning PCV valve can lead to several noticeable issues. Pay attention to these three key signs:

- Excessive oil consumption: If your vehicle is using more oil than usual, it may indicate a problem with the PCV valve causing improper oil circulation.

- Bluish-gray exhaust smoke during acceleration: This type of smoke suggests that oil is burning in the combustion chamber, often a result of a faulty PCV valve.

- Rough idle or engine misfires: An imbalanced air-fuel mixture due to a malfunctioning PCV valve can lead to inconsistent engine performance.

Recognizing these signs early can help you maintain optimal engine performance and prevent more serious damage. If you encounter any of these issues, consider a thorough inspection or replacement of the PCV valve. This proactive approach will enhance your engine’s efficiency and longevity.

Stay aware and keep your vehicle running smoothly!

How Do Positive Crankcase Ventilation PCV Valves Control Emissions Caused?

Understanding How PCV Valves Control Emissions

PCV valves play a crucial role in reducing emissions by redirecting your engine’s blow-by gases back to the intake manifold. This process significantly lowers hydrocarbon pollution because these gases burn rather than escape into the atmosphere.

How PCV Valves Function

- Blow-By Gas Redirection: The PCV system captures blow-by gases, which are the byproducts of combustion, and reroutes them into the intake system.

- Enhanced Combustion: By returning these gases to the combustion chamber, the engine utilizes them, leading to cleaner air.

- Emissions Reduction: This mechanism helps to minimize harmful emissions, making your vehicle more environmentally friendly.

Using Armor Lubricants in your engine can further optimize performance and longevity. Proper lubrication enhances the effectiveness of the PCV system, ensuring efficient gas redirection and cleaner emissions.

Benefits of a Functional PCV System

A well-functioning PCV system provides several benefits:

- Lower Hydrocarbon Levels: By burning blow-by gases, vehicles emit fewer hydrocarbons.

- Improved Engine Efficiency: Reintroducing gases helps maintain optimal engine performance.

- Extended Engine Life: Keeping emissions in check can lead to reduced engine wear and tear.

Regular maintenance and the use of high-quality lubricants such as Armor Lubricants can help maintain the PCV system’s function, leading to superb performance and lower emissions for your vehicle.

Should PCV Be Open or Closed at Idle?

Should the PCV Valve be Open or Closed at Idle?

At idle, the PCV valve should remain partially closed. This setup allows for optimized blow-by gas flow, which helps maintain the engine’s air-fuel ratio. A proper air-fuel balance prevents rough running and promotes engine efficiency.

Key Benefits of a Partially Closed PCV Valve at Idle:

- Optimizes Flow: Promotes effective blow-by gas circulation.

- Maintains Air-Fuel Ratio: Keeps the combustion process stable.

- Prevents Rough Engine Operation: Ensures smooth idling performance.

When the PCV valve operates correctly, it contributes positively to the engine’s performance. A fully open or fully closed valve can disrupt the balance and negatively impact engine function. Proper management of the PCV valve at idle creates a more reliable and efficient engine experience.

Always remember that callouts to specific lubricants, such as Armor Lubricants, can enhance your engine’s overall health. Prioritizing quality lubricants contributes to the longevity and performance of your vehicle.

Does a PCV System Help Increase Crankcase Pressure?

Does a PCV System Help Increase Crankcase Pressure?

No, a PCV system does not increase crankcase pressure; instead, it effectively reduces it. This system actively removes blow-by gases, maintaining a slight negative pressure in the crankcase.

Benefits of a properly functioning PCV system include:

- Prevention of oil leaks

- Reduction of engine damage

- Improved overall efficiency

By regulating crankcase pressure, the PCV system supports engine longevity and performance. Regular maintenance ensures that the PCV system operates effectively, safeguarding your engine’s health.

Understanding the role of the PCV system can help you maintain your vehicle better. Trust in Armor Lubricants for high-quality products that support your engine’s needs.

Conclusion

Maintaining a healthy PCV valve is essential for extending your engine’s life. Symptoms such as oil leaks, rough idling, and increased emissions signal a need for inspection or replacement. Addressing these signs promptly enhances performance and reduces your environmental impact.

Choosing the correct PCV valve for your specific engine ensures optimal crankcase ventilation, leading to better overall vehicle health. Regularly replacing a faulty valve can improve engine efficiency in the following ways:

- Reduces oil leaks

- Prevents rough idling

- Lowers emissions

Engaging in proactive maintenance keeps your vehicle running smoothly while contributing to a cleaner environment. Remember that a well-functioning PCV system plays a crucial role in your engine’s performance and longevity.